Fiberglass Mat Tensile Strength

Like any material fiberglass has advantages and disadvantages.

Fiberglass mat tensile strength. However in applications such as corrosion low to medium volume production very large parts contoured or rounded parts and parts needing high specific strength fiberglass is the material of choice. Fiberglass is the foundation of the composites industry. The most popular resins are polyester vinyl ester and epoxy. Reinforcements include fiberglass cloth fiberglass mat carbon fiber and aramid.

Fiberglass epoxy composite tensile fiberglass woven fabric flexure epoxy matrix interlaminar shear single lap shear 0. Compared to structural timber extren industrial fiberglass has a higher flexural strength with outstanding resistance to extreme bending. Fiberglass is a designer s ideal material because the parts can be tailored to. G 10 is used for terminal boards high humidity applications electrical and electronic test equipment and electric rotor insulation.

Three flat panels of. The strength of structural timber varies depending upon the species and treatment methods used to preserve the wood. It exhibits a tensile strength of up to 30 000 psi and a flexural modulus of 10 000 psi. Fiberlgass is used in a wide assortment of projects within the industry.

It is lightweight has moderate tensile strength and is easy to handle. In brittle materials the ultimate tensile strength is close to the yield point whereas in ductile materials the ultimate tensile strength can be higher. It also has excellent tensile strength but poor compression strength. It certainly gives the board a specific flex and is very white but it does cost a little bit more.

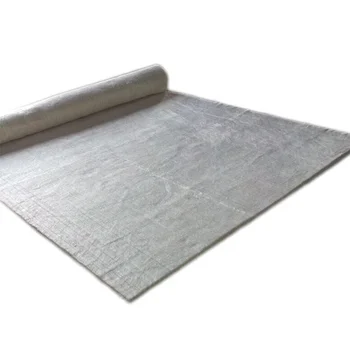

It s a pretty cool fiberglass that guys either love or hate. Fiberglass american english or fibreglass commonwealth english is a common type of fiber reinforced plastic using glass fiber the fibers may be randomly arranged flattened into a sheet called a chopped strand mat or woven into a fabric the plastic matrix may be a thermoset polymer matrix most often based on thermosetting polymers such as epoxy polyester resin or vinylester or a. Direct sized fiberglass undergoes a finishing process which allows for increased tensile strength and a brighter whiter finished product. Resin holds the reinforcement together and helps it conform to the wanted shape.

It s been used in many composites applications since the 1950 s and its physical properties are pretty well understood.