Floor Space In Value Stream

The other schedulers along with certain shop floor supervisors would become value stream leaders in charge of production areas and reporting to the value stream managers.

Floor space in value stream. Choose one value stream to begin with. Step 1 understand value. Number of rejects. Value stream maps fulfill that desire.

The first step to developing a value stream map is to understand the concept of value adding activities. Value stream mapping also known as material and information flow mapping is a lean management method for analyzing the current state and designing a future state for the series of events that take a product or service from the beginning of the specific process until it reaches the customer a value stream map is a visual tool that displays all critical steps in a specific process and. You and your team learn most from drawing the value stream. Bradshaw called the plant s human resource hr manager into his office in the spring of 2003 to discuss plans for the new organization.

Value stream maps are often pushed by consultants that need to familiarize themselves with the shop floor of their client. Hence involve the group unless you are a team of one. Value stream mapping can be used to improve any process where there are repeatable steps and especially when there are multiple handoffs. Value stream mapping vsm is a lean manufacturing technique used to analyze design and manage the flow of materials and information required to bring a product to a customer.

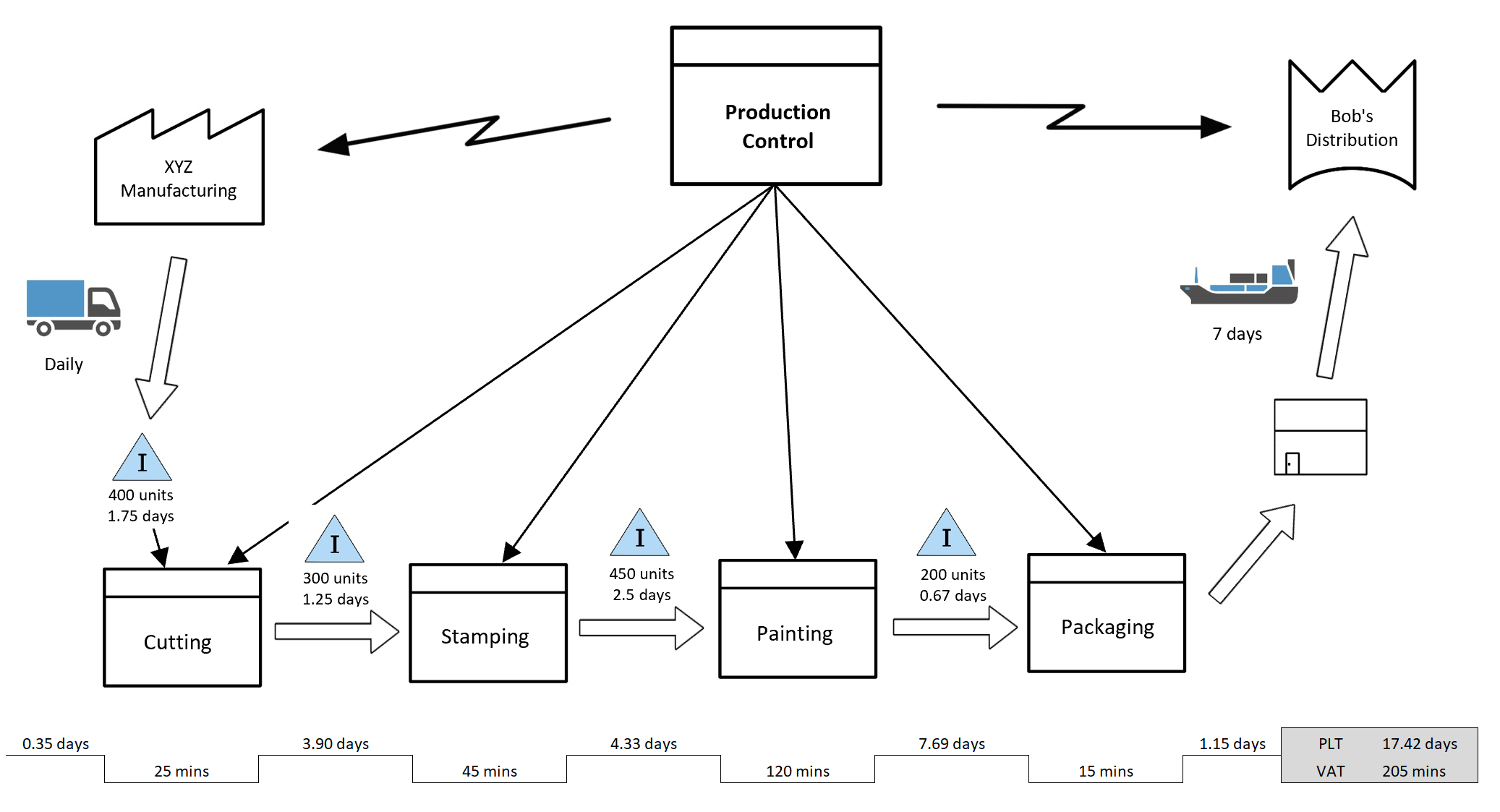

Value stream map vsm what is value stream mapping vsm a value stream map illustrates the flow of materials and information from supplier to customer. In manufacturing handoffs are easier to visualize because they usually involve the handoff of a tangible deliverable through stations. Yet having a value stream map and improving the shop floor are not one and the same. Feet 66 12 bins to 4 bins benefits reductions increased predictability of output and adherence to takt time elimination of ergonomic issues associated with manual bin transfer.

Reduced hrs part floor space and inventory hrs part. For me the value of a value stream is doing the value stream map not having one. The value stream map is full of pictures and friendly symbols which make it a simple tool to understand and develop. If on the other hand one person of the team does the value stream alone and then presents it to the others nothing is learned by the others.

23 6 9 to 5 3 20 5 to 4 1500 sq. Additionally in western companies management often likes fancy slides and frilly charts. Value stream map vsm a tool used to improve a process by identifying added value and eliminating waste a process map that follows the value creation process strap yourself to the product or service and see where you go a process map with data added times. Processing wait cycle quality.