Fiberglass Mat Vs Cloth Subwoofer

Since 1984 i ve been involved in building five different fiberglass airplanes.

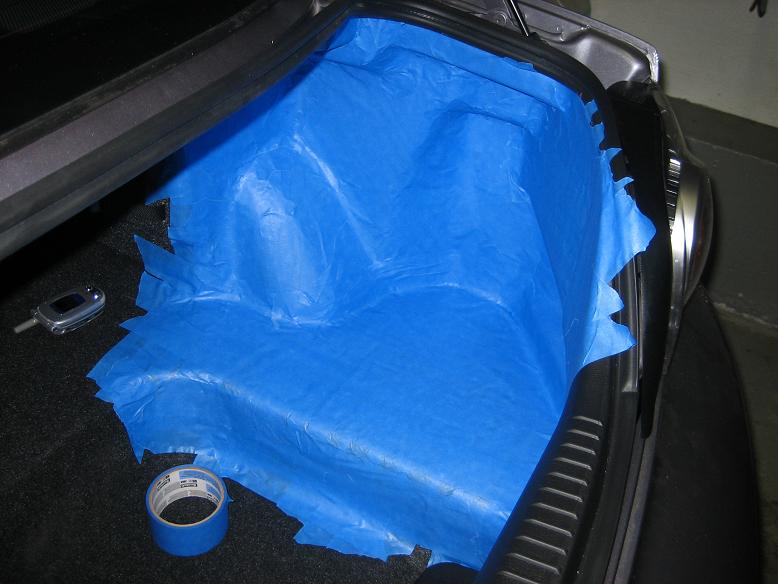

Fiberglass mat vs cloth subwoofer. Wow im surprised you guys all perfer mat. Like so many other things it is a combination that yields best results. Mat is only compatible with polyester and vinyl ester resin. Most automotive applications like a subwoofer box use cheap resin mat cloth for economy and the fact that mat lends itself to quick finished products and is good for one off projects.

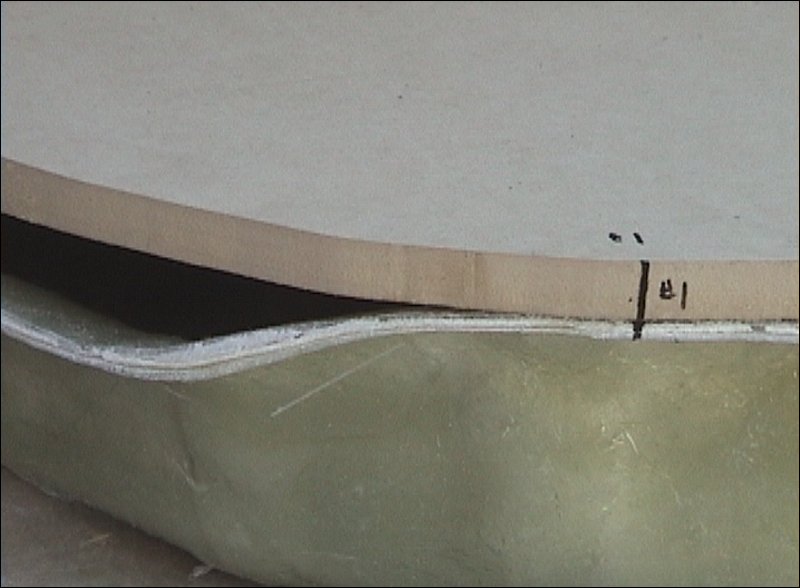

It is used in a great variety of applications. If the fiberglass skin is 1 8 thick the width of the bevel will be at least 1 long. All its weaves are random. Fiberglass cloth also known as fiberglass fabric is an excellent choice when you are looking for a strong light weight part.

The mat is good for sub boxes for itâ s strength in all directions and the cloth hold everything together. Use fiberglass cloth when you are looking to create a strong light weight product. I turned out doing mat cloth mat cloth ect for 7 layers. A question i receive often is how many layers of fiberglass do i need for a fiberglass subwoofer box door pod a pillar etc unfortunately there is not a.

During construction fiberglass mats are layered until the desired strength or thickness is achieved. Those little freys always gets stuck to everything. Perhaps a layer of cloth and 2 layers of mat the layer of cloth and then more matt â until desired thickness is achieved. Cloth fiberglass cloth is a layer of woven strands.

The strands of fiberglass in a mat are disorganized and can intermesh easily with the fibers of other mats so they bond together. But the cloth doesnt seem as strong. All of our fabrics must be used with a resin system polyester vinyl ester or epoxy to create a composite part the fiberglass is what gives any part it s strength. Changing the angle of the stictch on the weave makes it much stronger i think this is why matt is a good strength enhancer.

The distance of the cut line and the bevel back from the corner is 12 times the fiberglass thickness. In not one of them was any mat cloth used. And this creates a structure in all directions inside the material as said the downside is that its not easy to work with. The fibers are randomly oriented.

It frey s easily and loves to stick to everything espically the brush from what ive done with it. Its kinda annoying when you rip them. And it seems a lot hard to soak them with resin become clear then the cloth. Chopped strand mat also known as fiberglass mat has short strands of fibers held together with a resin binder.

A 12 to 1 bevel allows room for multiple layers of fiberglass fabric and epoxy across the cut line to restore strength to the fiberglass skin. Fiberglass mat has a higher density than fiberglass cloth. Then i ll use thin strips of 1 5 oz mat along the seams of the 3 oz mat.