Epoxy Flooring Procedure Pdf

Eliminate any source of direct air blowing onto the surface.

Epoxy flooring procedure pdf. To do epoxy flooring you ll need to clean the floor and apply the covering with a roller. They are able to provide a number of performance functions such as slip resistance chemical resistance and abrasion resistance. We know that you have many choices when selecting a floor coating but not all coatings yield the same quality of results like epoxy coat. First scrub your floor to remove grease sand any rough patches and vacuum up debris.

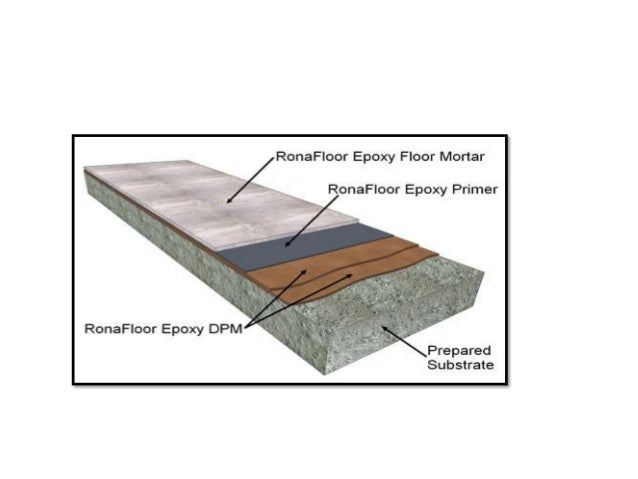

The epoxy risen floor coating system is usually used in hangars warehouses and many other places. Prime the floor with a suitable epoxy primer. Failure to follow this procedure will result in excessive deposits of dirt in the anti skid areas and may cause long term damage to your flooring system. Epoxy flooring systems resurface concrete floors and add color to designate walkways or other markings.

Epoxy floor coating problem solving guide page 10 prevention. Then clean the entire floor thoroughly with a pressure washer to remove any impurities. Spike rollers can be used if bubbles appear but may not completely remove them. The price itself is pretty affordable but considering all the advantages it has over some other kinds of flooring the calculation is clear this is one of the best investments you will ever make whether.

Always prime the floor don t believe claims that priming is not necessary. Because of this characteristic it has been shown to be the most suitable coating system for huge ground floor areas that would carry heavy vehicles like aircraft and forklifts. For more information about this product or any other epoxy systems product please contact. Epoxy primer epoxy underlay epoxy polyurethane self leveling coat application instructions.

Epoxy flooring long lasting attractive floors for industrial or commercial use. Once the floor is dry start applying a coat of epoxy primer. Use a primer system on all porous concrete. Follow directions for mixing and using primer.

Meticulously engineered and formulated by a team with over 35 years of experience in concrete floor coating our products are manufactured in michigan with top notch components so you ll only have to do it once. An epoxy risen floor coating system has the ability to withstand pressure from heavy loads and objects. Neoquartz neoquartz rts 1 8 100 solids epoxy or polyaspartic broadcast system with color quartz aggregate. On top of everything installing this black epoxy metallic floor coating system is one of the most cost effective solutions for anybody.

All dust and debris should be removed prior to application of the. It is essential that surface should be sound clean and dry surfaces in order that maximum bond strength is achieved between the substrate and the flooring system. Vacuuming dust from epoxy floor priming and filling.