Electrically Conductive Materials Are Cut By Wedm Process By

Micro edm is a recognized machining process for electrically conductive materials to makes micro features micro holes on difficulty to cut materials electrically conductive metal and alloys.

Electrically conductive materials are cut by wedm process by. Material removal takes place by a series of discrete discharges between the wire electrode and workpiece. Wire electrical discharge machining wedm is an electrothermal non traditional machining process used for machining electrically conductive materials that are difficult to machine. It is fed in the programmed path and material is cut removed from the workpiece accordingly. In wire edm the conductive materials are machined with a series of electrical discharges sparks that are produced between an accurately positioned moving wire the electrode and the workpiece.

High frequency pulses of alternating or direct current. The spark theory on a wire edm is basically the same as that of the vertical edm process. Of course some electrically conductive materials still don t play well with edm. Wire electrical discharge machining edm is a process of metal machining in which a tool discharges thousands of sparks to a metal workpiece.

In the wedm process the motion of the wire is slow. I ve been asked to cut silicon wafer material which is almost glass like said greg langenhorst technical marketing manager at mc machinery. It s way too brittle and the spark energy just shatters it like glass. That doesn t work too well.

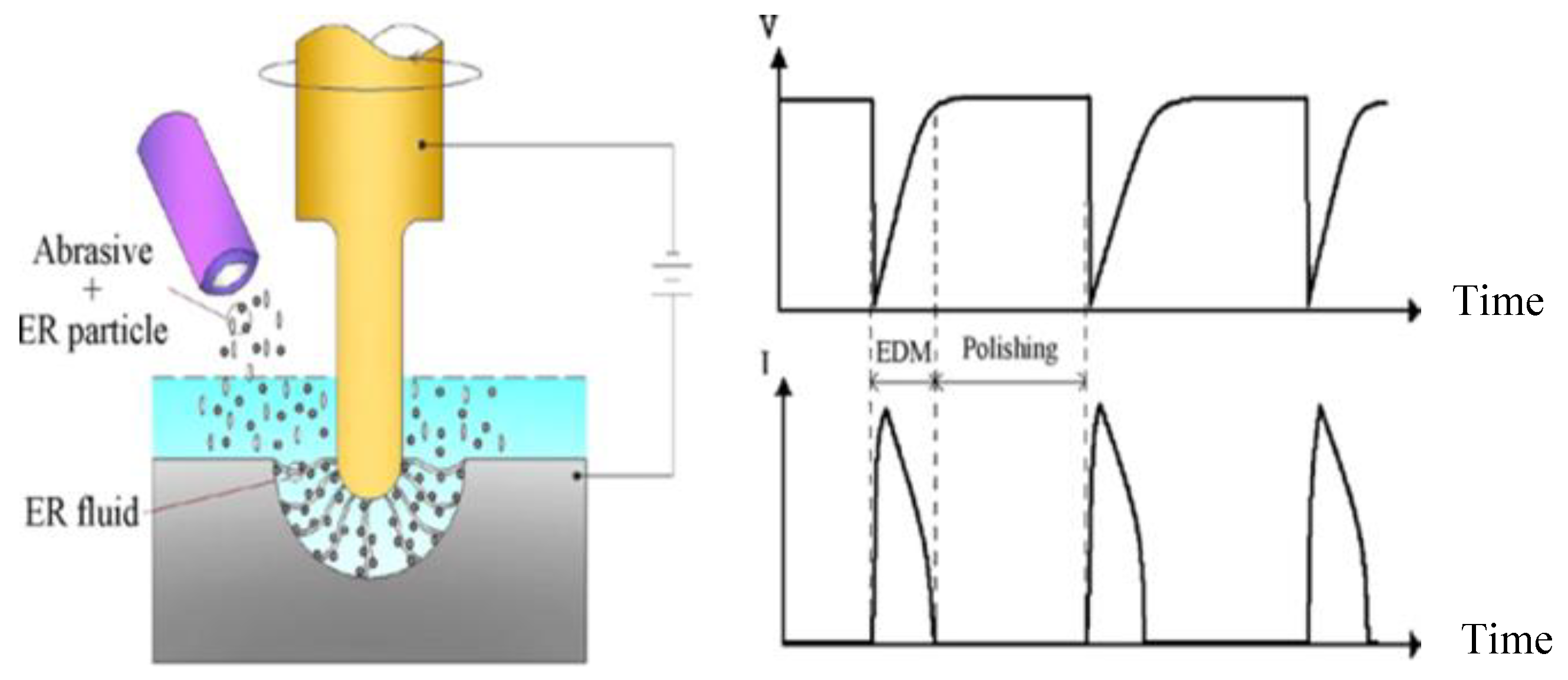

Wire electric discharge machining wedm has become a widely accepted electrothermal process for electrically conductive materials. Wire electrical discharge machining is a high precision method for cutting nearly any electrically conductive material. Electrically conductive materials are cut by wedm process by an electro thermal mechanism. In this regard us patent 20100012628a1 presents a hybrid wire embedded with electrically nonconducting abrasives as shown in figure 35 in this process two body abrasion is used to improve material removal through electrical erosion.

It is fed in the programmed path and material is removed from the workpiece accordingly. A non conventional process though hardly a new one wire edm works on parts resistant to conventional machining processes but only if these parts are electrically conductive. Especially nickel based alloy titanium alloy and other heat resistant metal alloys whereas micro edm could successfully applied in machining of any electrically conductive materials. Electrically conductive materials are cut by the wedm process by the electro thermal mechanisms.

Usually they are non ferrous and. The edm wire research currently focuses on achieving higher machining speed and surface integrity.